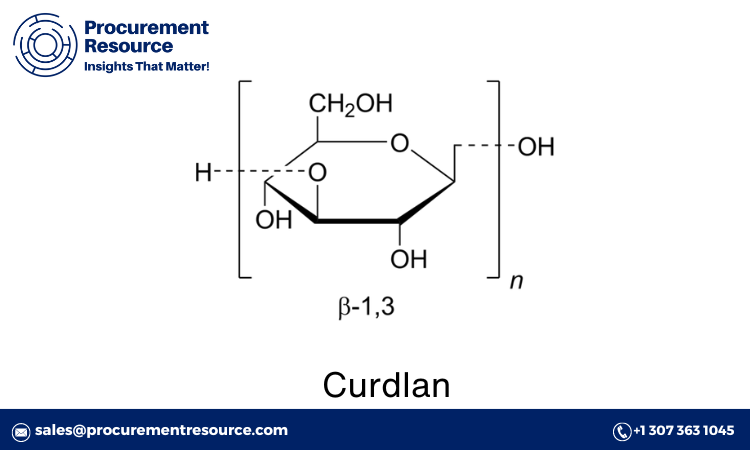

Curdlan is a polysaccharide produced by certain strains of bacteria, primarily from Agrobacterium and Alcaligenes species. It is known for its unique ability to form a gel upon heating, making it a valuable ingredient in the food and pharmaceutical industries. The production of curdlan involves a sophisticated fermentation process, where specific bacterial strains are cultivated under controlled conditions to synthesize the polysaccharide. Understanding the intricacies of this process is crucial for determining the cost structure of curdlan production.

The production process of curdlan is typically divided into several stages, beginning with the preparation of a suitable culture medium. This medium, rich in carbon sources like glucose, provides the necessary nutrients for the bacterial strains to thrive and produce curdlan. Once the medium is prepared, it is sterilized to eliminate any contaminants that could interfere with the fermentation process.

The bacterial strain is then introduced into the sterilized medium in a fermenter. Under optimal conditions of temperature, pH, and oxygen supply, the bacteria produce curdlan as an extracellular polysaccharide. The fermentation process can take several days, depending on the bacterial strain and the desired yield. After fermentation, the curdlan is separated from the bacterial cells and other byproducts through a series of filtration and centrifugation steps.

Request For Sample: https://www.procurementresource.com/production-cost-report-store/curdlan/request-sample

Manufacturing Report and Process

The manufacturing of curdlan on an industrial scale involves several key steps that contribute to the overall production cost. The first step in the process is the selection and preparation of raw materials. These include the carbon source (usually glucose), nitrogen source, and other essential nutrients required for bacterial growth. The quality and cost of these raw materials significantly influence the cost of curdlan production.

Once the raw materials are prepared, the fermentation process begins. This involves the cultivation of the bacterial strain in a fermenter, where the conditions are carefully monitored and adjusted to maximize curdlan production. The fermenter is equipped with sensors to control parameters such as temperature, pH, and oxygen levels, ensuring optimal conditions for bacterial growth.

During fermentation, the bacteria metabolize the carbon source to produce curdlan. The duration of this process varies depending on the bacterial strain and production scale. After fermentation, the culture is subjected to a series of downstream processing steps to extract and purify the curdlan. This includes filtration to remove bacterial cells and other impurities, followed by centrifugation to concentrate the curdlan.

The final step in the manufacturing process is the drying and packaging of curdlan. The purified curdlan is typically dried using spray drying or freeze drying techniques, which reduce the moisture content and increase its shelf life. The dried curdlan is then packaged in suitable containers for storage and distribution.

The efficiency of the manufacturing process, along with the cost of raw materials, labor, and energy, plays a significant role in determining the overall production cost of curdlan. Advances in fermentation technology and process optimization can lead to cost reductions, making curdlan production more economically viable.

Raw Material Costs

The cost of raw materials is a critical factor in the overall cost of curdlan production. The primary raw material used in the production of curdlan is the carbon source, usually glucose. The price of glucose can fluctuate depending on market conditions, which in turn affects the cost of curdlan production. Additionally, other raw materials such as nitrogen sources, minerals, and vitamins are required to support bacterial growth and curdlan synthesis.

The quality of raw materials also impacts the production cost. High-quality, pure glucose ensures efficient fermentation and higher yields of curdlan, but it may come at a higher cost. On the other hand, lower-quality glucose might reduce production efficiency, leading to higher costs in the long run due to lower yields and increased downstream processing requirements.

Another significant cost factor is the scale of production. Large-scale production facilities may benefit from economies of scale, where the cost per unit of raw material decreases with increasing production volume. However, the initial investment in large-scale equipment and infrastructure can be substantial, affecting the overall cost structure.

In addition to glucose, the cost of water, electricity, and other utilities used in the fermentation and downstream processing stages also contributes to the raw material costs. Efficient use of these resources can help reduce costs, making curdlan production more competitive.

Latest News

The curdlan production industry has been witnessing significant developments, driven by advancements in fermentation technology and increasing demand for curdlan in various applications. Recent innovations in microbial engineering have led to the development of new bacterial strains with enhanced curdlan-producing capabilities. These strains are capable of producing higher yields of curdlan in shorter fermentation times, which can potentially reduce production costs.

Furthermore, the food and pharmaceutical industries’ growing interest in curdlan due to its unique gelling properties has spurred research into optimizing production processes. This includes the exploration of alternative, cost-effective carbon sources for fermentation, which could further drive down production costs.

In the global market, curdlan’s demand is expected to grow, particularly in regions where the food industry is expanding. Asia-Pacific, for instance, has seen a surge in curdlan use as a food additive, driven by the growing processed food industry. This has led to increased production capacities in the region, with several companies investing in new production facilities to meet the rising demand.

Moreover, sustainability concerns have prompted companies to explore eco-friendly production methods. This includes reducing the environmental impact of curdlan production by optimizing resource use and minimizing waste generation. Companies that adopt sustainable practices may gain a competitive edge in the market, particularly as consumers and regulators increasingly prioritize environmental responsibility.

In conclusion, the curdlan production industry is poised for growth, with ongoing innovations and market developments shaping its future. As demand for curdlan continues to rise, particularly in the food and pharmaceutical sectors, understanding the cost structure of its production will be crucial for companies looking to capitalize on this growing market.